Solar FAQ

SOLAR PANEL BASICS

What does efficiency relating to solar panels mean?

Solar panel or solar PV efficiency is a sliding scale from 0 to 100 percent. 100 percent efficiency is based upon 1000 watts being generated in one square meter. This calculation is based upon what an average noon day sun will produce in strong sun. In other words if you had a solar panel that was exactly 1 square meter in size and it produced 1000 watts that panel would be 100% efficient. Anything less than 1000 watts would be a percentage of efficiency.

As of 2021 the typical rigid glass solar panel is 39 inches wide by 65 inches long or 1.635 square meters (2535 square inches) and produces an average of 250 watts. If the panel produced 1,635 watts it would be 100% efficient. But since it produces only 250 watts that equates to an efficiency of 15.3 percent.

Why have all the flexible solar panel manufacturers gone out of business?

Domestic, USA based manufacturing of solar cells and panels have shifted overseas as the cost of materials and labor can be found at lower rates.

How many panels do I need to get xKW of power?

Divide the total wattage of your project targets by the individual wattage of the solar panel series you are interested in. For a 4000 watt system, a full carton of 30 of our 128W Uni-Solar PVL-128 panels would create almost enough at 30 panels x 128 W/each = 3840 watts of total power.

How do I figure output per month on solar panels?

It depends on how much sun and how strong the sun is at your location. Also it depends what time of year ie. winter vs summer. For us here in Southern California a general rule of thumb is 3-4 hours per day during summer. Maybe half that during winter. So if we have 1000 watts of solar panels on our roof we can generate 3000 to 4000 watts per day during summer and about 1000 to 2000 watts during winter. Multiply the daily output by the number of days in the month to get monthly output.

How does the quality of a Xunlight panel compare to a Unisolar panel?

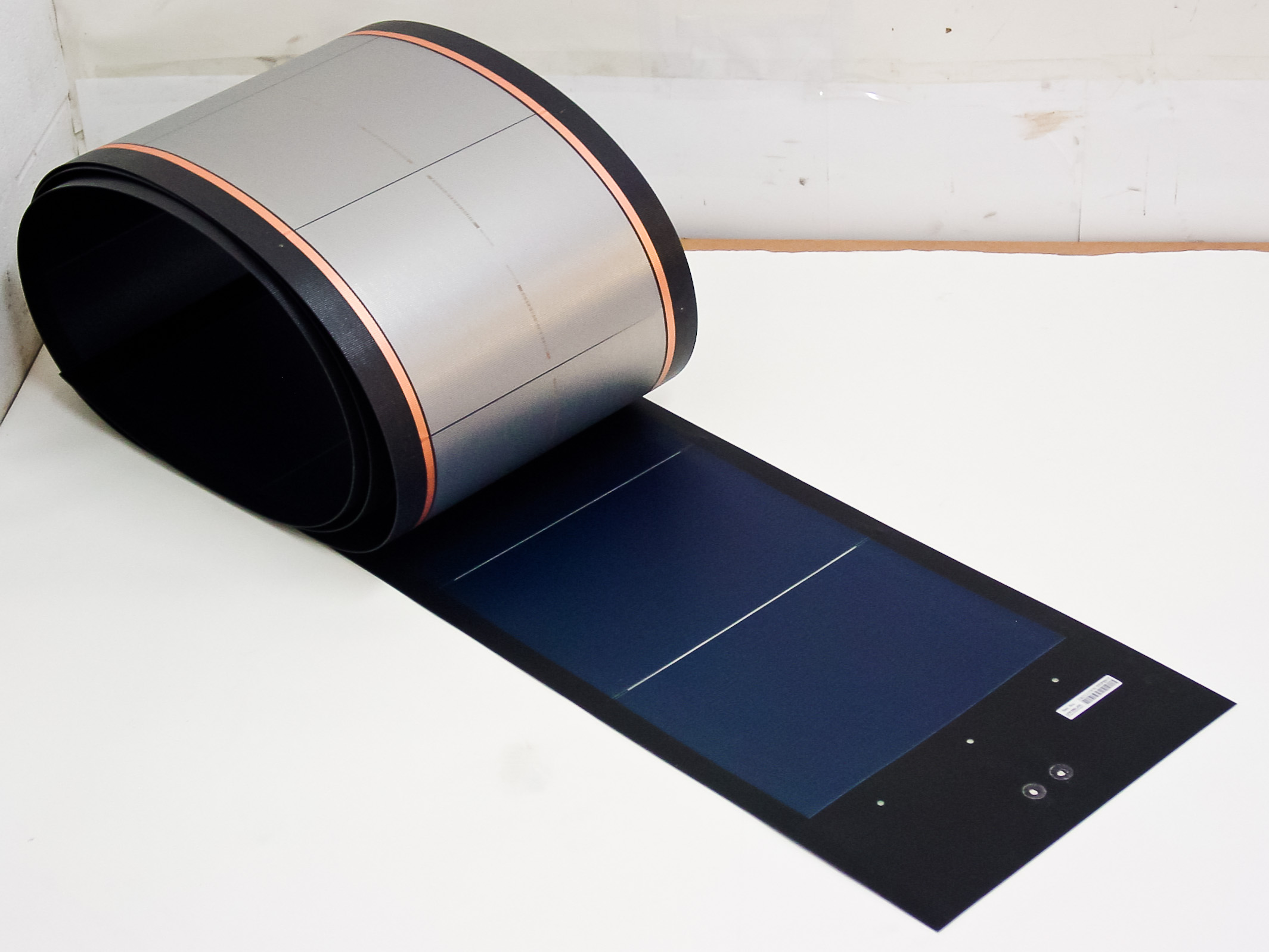

Unisolar is our highest quality panel and does have the peel and stick backing installed at the factory. The Xunlight panels use the same solar cell technology but the encapsulation appears to be of lower quality and also none of the Xunlight panels have peel and stick backing. If it were my project and I wanted it to last for multiple years I would select Unisolar even if the wattage is lower, just because its a higher quality panel.

What panels can I use with a 24v system?

Answer is Coming Soon...

Will these panels work on my roof, boat, project, etc…?

Answer is Coming Soon...

SOLAR PANEL CONNECTORS

What kind of connectors do your various panels have?

We have solar panels from various manufacturers. There are MC3, MC4, TE SolarLok, Amphenol Helios H4 connectors and SAE Plugs, plus panels with Solar Points, Metal Tabs and 4-Inch Wires. There are plenty of variants and form factors to fit multiple situations.

Why do solar panels have various types of connectors and what are the differences between them?

Multi-Contact (Stäubli Electrical Connectors), Amphenol and TE Connectivity and others have all created their own types and features for solar panel connectors. They have even changed their own designs over the years as they create safer and easier options. Please make sure you identify the connectors on any panels you are interested in, and compare them to the other devices in your array.

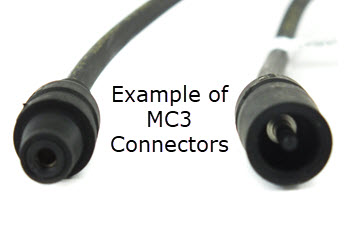

MC3 connectors are a simple rubber coated, push-pull connector with no safety latches.

MC4s are plastic and have safely latches than CAN be un-latched by hand or with a tool.

Amphenol Helios H4 connectors VERY SIMILAR to MC4s but cannot be un-latched by hand and do require a special tool to decouple - so be careful when playing with the H4 connectors.

TE SolarLok connectors are round in shape and their safety tabs can be un-latched by hand and no tool is needed.

Which types of connectors are “modern” and still in use?

MC4 connectors are believed to be the most popular at the moment. Amphenol’s Helios H4s are compatible with them, but they require a tool to un-connect them. TE SolarLok connectors are still in use but seem to be less prevalent.

Are connector adapters available if I want to change a panel’s native connectors?

Yes, adapters are available on many marketplaces. Running an online search for “SolarLok to MC4 Adapter” or similar might bring up relevant results.

SOLAR PANEL ACCESSORIES

Do the panels come with everything I need to connect them?

Every panel has a positive and negative connection regardless of connector type - so every panel is ready to produce power, however, you may need extra wires, connectors, cabling and more to dial-in the setup for your project.

What inverter do I need or will the inverter I have will work with a certain panel?

Compare the Open Voltage (Voc) and Short Circuit Current (Isc) of your panel/array to the max limits supported on your inverter or charge controller. If you have many panels, you may need to get creative and connect some groups in Series and connect those groups together in Parallel, etc., to keep below your max limits.

Do you sell inverters and other connection accessories?

We do not carry inverters or charge controllers. We have a small selection of cables and connectors in the form of MC3 and MC4 Junction Boxes.

I have an “off grid” solar setup on my RV to keep an onboard battery bank topped off. What charge controllers would work with your panels and my existing batteries?

When choosing a Charge Controller for our flexible Unisolar, Xunlight, or Solopower solar panels you need a one that can handle the open circuit voltage of your panel(s) and can step down the higher voltages to charge either 12 volt or 24 volt battery banks. The following Tracer models have been tested to work well to charge 12 volt batteries with very little loss in power.

Tracer 2210A 20A can handle 4 panels

Tracer 3210A 30A can handle 6 panels

Since the flexible solar panels we sell can have open circuit voltages of 60 or more volts these Tracer charge controllers are compatible since they can handle open circuit voltages up to 100 volts.

SOLAR PANEL INSTALLATION AND USE

Can I create top cable access on panels with bottom solder points?

The bottom facing solder point can have the wires coming out the top. What you do is drill through the center of the solder point. Then you have two options to bring the wires out through the top.

- Option 1 Drill hole through the center of the solder point. Push solar cable wire through the top so it pokes out the bottom of the panel. Then fan the wires and solder. After solder caulk the bottom solder point area. This option was suggested by a Uni-Solar panel reseller.

- Option 2 is go to Grainger website and search for 5UGN4 and buy a pack of 100 of bare screw disconnects. Here's a link. Drill hole through the center of the solder point and attach connector with the terminal block facing the top side with screw on the bottom. Then solder the screw connector from the bottom. Now you have a top facing tab that you can attach solar wires to. Once solar wires are attached caulk exposed metal. This option was suggested by a long time Uni-Solar dealer and installer.

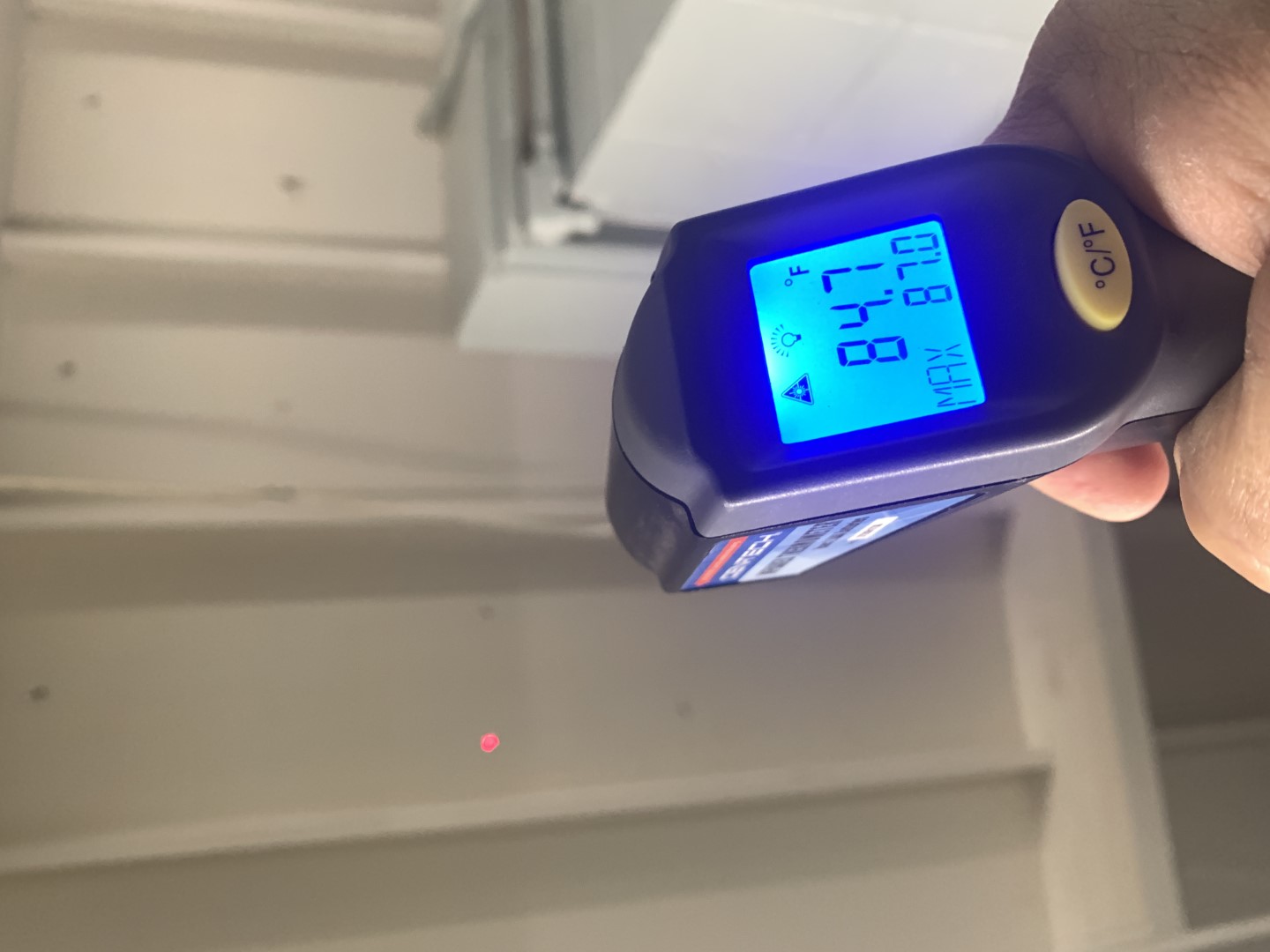

Does installing solar panels make the roof hot and degrade either the roof or panels?

The short answer is NO. We did temperature readings on our roof to illustrate this showing only slightly higher temps where panels were installed.

Temperature of Panels as Installed on Roof: 113.7° Temperature of Roof without Panels Installed: 109.2°

Temperature Under Roof w/Panels: 89.4° Temperature Under Roof Without Panels: 84.7°

Here's a link with more information: https://www.sciencedirect.com/science/article/abs/pii/S0038092X18309733

Should I connect in series or parallel?

Wiring solar panels of different voltages or currents can be done in either series or parallel - but this will lower the overall wattage of the system and will not be as effective. When different panels are connected in series, the voltages are added up as usual but the current is capped at the lowest Amp rating in the chain. When connected in parallel, the current is added up as usual but the voltage is capped at the lowest voltage panel in the chain. As long as your charge controller’s V or A limits are passed, panels of different ratings may be connected together in a less-efficient array.

Can solar panels be cut or trimmed?

Answer is Coming Soon...

How much trimmable edge do panels generally have?

Normally, there's a few inches on each side. The Xunlight panels have a bit more "edging" because they are still untrimmed to some degree. Since they have no sticky backing, it would be easier to make a "tighter" trim using the Xunlight panels.

Can I drill mounting holes into the edges of any of your solar panels?

Uni-solar did not suggest drilling holes in the panels as it could hit the copper bus that runs along the edges and also opens up the encapsulation to air/water. That said, in the past we did get a carton of the PVL-128 series that were see-through on the back. Here are some photos we took at the time. We sold out of them many years ago. (https://www.recycledgoods.com/uni-solar-pvl-144b-144-watt-brand-new-top-solder-point-solar-panel-no-adhesive/)

I have heard of it being done successfully but I have also heard of many panels being damaged by doing that as well. The best way to attach wires is soldering to the solder point. We have a hard time getting the j-boxes to stick to the ETFE panel top sheet so you might just solder your solar wires directly to the solder point and then caulk that area up. Grainger sells a screw type lug 5UGN4 that an old time Uni-Solar installer turned us onto. He said he drilled the center of the solder point and added those lugs and then screwed in from the bottom with top side connector. Then you can solder to that.

How can I determine which connectors are Positive and Negative?

A multi-meter applied to both connections will read a voltage when the panel’s cells are exposed to sunlight. If the reading does NOT show a negative “ - “ symbol in front of the voltage reading, then your Positive and Negative test probes are connected to the proper Positive and Negative connectors on the panel. If the “ - “ DOES appear, switch the multi-meter’s test probes and then you’ll have located the + and - terminals.

How do I connect a Junction-Box (J-Box) to a panel without native connectors?

Answer is Coming Soon...

I have a metal roof on my house, how do I attach the Uni-Solar Peel-and-Stick solar panels to the building?

The peel-and-stick backing can become TOO GOOEY and not peel off correctly when the panels are warm/hot. It is recommended to cool or heat the panels to approximately 72°F / 22°C for best results. Testing a corner of the white protective layer will provide some feedback as to the panel’s readiness. We’ve heard stories of folks cooling their panels inside a car with the AC running prior to installation.

I have an RV, how do I attach the Uni-Solar Peel-and-Stick solar panels to the roof?

According to what we understand, the peel-and-stick panels have a very strong bond when correctly applied and require extreme heat to remove - such as a blow torch - that will destroy the panel and may cause harm to the mounted surface. We have heard of folks peeling a 2-inch wide strip every 2-feet on the panels’ protective white backing and mounting metal plates on the panels themselves that stick out a few inches on each side of the panel. With that they mount the metal strips - not the panel - to the surface and therefore make removing the panel in the future simply a task of unscrewing the metal strips, and not un-sticking the panel.

What does “Solar Cell Sun Soaking” mean on your Global Solar and SoloPower panels that utilize CIGS cells?

These panels are new but have been in storage for awhile. They will typically output about 50% of their rated capacity out of the box. It will take 2-3 days of sun soaking to come to full power. To accomplish this, just lay them out in the sun. This is common with all CIGS Solar panels.

Can I remove the buytl sticky backing off my Uni-Solar panel?

The sticky backing cannot be removed from the panel. From what we have read, removing the sticky back from a metal roof involves a blowtorch and destroying the panel during uninstallation. If you're looking for a flexible solar panel without the peel and stick Buytl backing similar to Uni-Solar panels you're in luck. Recently we purchased the remaining stock of Xunlight panels which are very similar in design but with no sticky backing. See Xunlight panels HERE.

SOLAR SHINGLES

How many Unisolar Solar Shingles do I need to roof my house?

Each solar shingle will have approximately 3 square feet of exposed cells that measure 86.5" x 5". (7-foot, 2.5-inches by 5-inches) - so depending on your roof's dimensions several shingles can be stacked together to power your home.

Are the solar shingles hard to install?

A licenced contractor should be consulted for any construction performed on a residential or commercial roof. We have some installation documentation from the manufacturer and they can be found on this page: SOLAR DOCUMENTATION

SOLAR CELLS

Can solar cells be cut?

The Solopower cells can be cut in one direction, allowing the cell to produce the same voltage but lowering its current. NanoCells CANNOT be cut as doing so creates a short between the extremely thin layers of materials. Our Uni-Solar L-Strip cells cannot be modified, but are the easiest to connect to each other with traditional soldering methods.

What are the positive and negative connections?

Uni-Solar L-Strip Cells: The protruding metal tabs are the positive connections. The edge-strips along the back sides are the negative connections.

Solopower Cells: The top ‘white lines’ on the solar side of the cell are the negative connections. The entire underside is the positive connection.

NanoCells: The sun-facing metal strip and 95% of the underside is the negative connection and the small strip on the underside is the positive connection.

How do connect cells together?

Uni-Solar L-Strip Cells: these can be soldered using a traditional method. We have also heard that double-sided conductive tape transmitted power cell-to-cell but was less reliable.

Solopower Cells: Ultrasonic welding was used by the manufacturer to connect banks of cells. We have also heard that double-sided conductive tape transmits power cell-to-cell but is less reliable.

NanoCells: Similar to the Solopower Cells, ultrasonic welding was used by the manufacturer to connect banks of cells with double-sided conductive tape transmitting power cell-to-cell but proving less reliable. Another user found that a special, chemically appropriate solder was able to connect to the nickel-plated surface on one of the connecting strips and held a reliable bond.

SOLAR TROUBLESHOOTING

Why is the output I am getting so low?

Every manufacturer rates their panels from the “Peak Stats at 100% Factory-Perfect Simulated Sun”. That being said you should be obtaining 80% of their values at solar noon during summer time. Check your local weather, the panels location and orientation, and even the angle at which the panel faces the sun.

How do I get sticky residue off panels (from packing, shipping, storage)?

Sometimes the backing gets on the front of the next panel based upon how it was stored and/or shipped. For small areas of residue, you can generally scrape it off with your fingers or a non-abrasive pad. Use 70% rubbing alcohol and a paper towel to remove the rest.