Nanosolar Panels and Cells

We have new Nanosolar Nanocell Flexible DIY Solar Cells in stock.

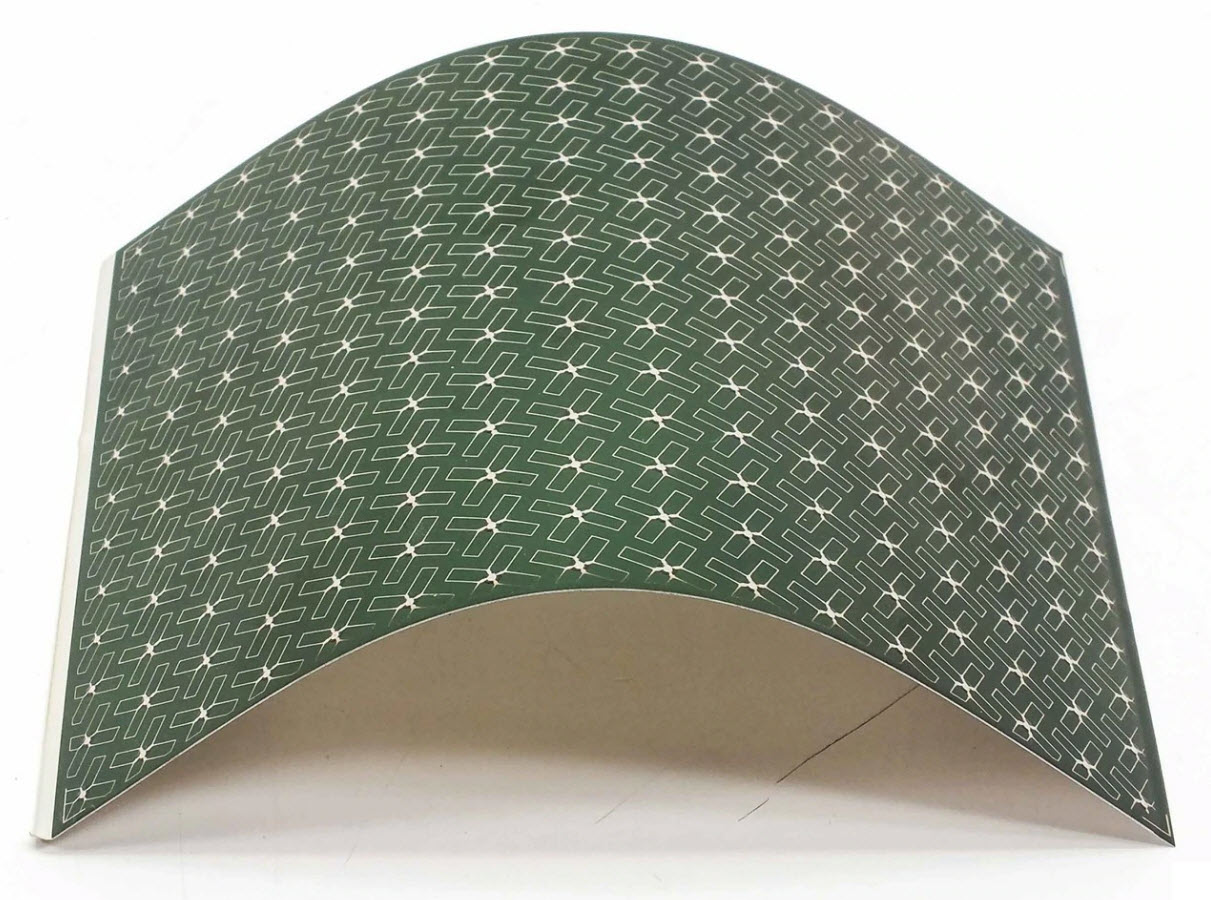

These raw flexible solar cells are extremely rare and have never been offered for sale to the public before. They are available individually, or if you would like larger quantities, we can ship these in bin racks of 1,000 cells and cartons of 6,000 cells.

These are tough little cells

These raw solar cells are very robust for CIGS (short for copper indium gallium selenide solar cells), however, as with all solar cells, they will degrade if not encapsulated in weather tight enclosure. For experiment, we have left a few of these outside exposed and un-encapsulated for two years and have found minimal degradation.

Here's a video we made testing the power output of Nanosolar Nanocell Flexible DIY Solar Cells:

Made in the USA

Our Nanocell inventory was manufactured at the Nanosolar facility in San Jose, California. Cells were tested for proper output by Nanosolar before being packaged, and we have found these are very robust cells. These solar cells can be previewed at our facility in Ventura, California.

Nanosolar Nanocell Flexible DIY Solar Cells

| Item | Brand | Watts | Weight | Length | Width |

| Nanocell 2.6W 1 | Nanosolar | 2.6 | 18.5g | 6.5" | 5.3" |

| Nanocell 2.6W 10 | Nanosolar | 2.6 | 18.5g ea | 6.5" | 5.3" |

| Nanocell 2.6W 1000 | Nanosolar | 2.6 | 18.5g ea | 6.5" | 5.3" |

| Nanocell 2.6W 6000 | Nanosolar | 2.6 | 18.5g ea | 6.5" | 5.3" |

Nanosolar Solar Panels

| Item | Brand | Watts | Connector | Weight | Length | Width |

| Utility 160 | Nanosolar | 160 | MC3 | 13.2 lbs | 76.25 in | 40.75 in |

DIY Tips and Tricks

Connecting solar cells

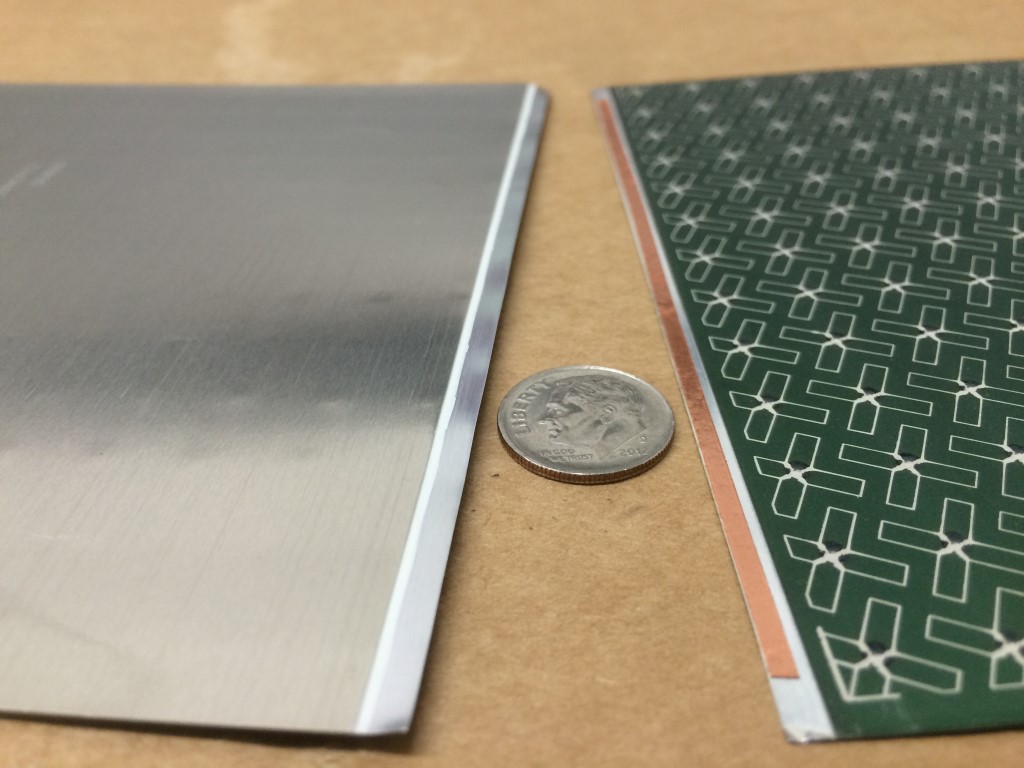

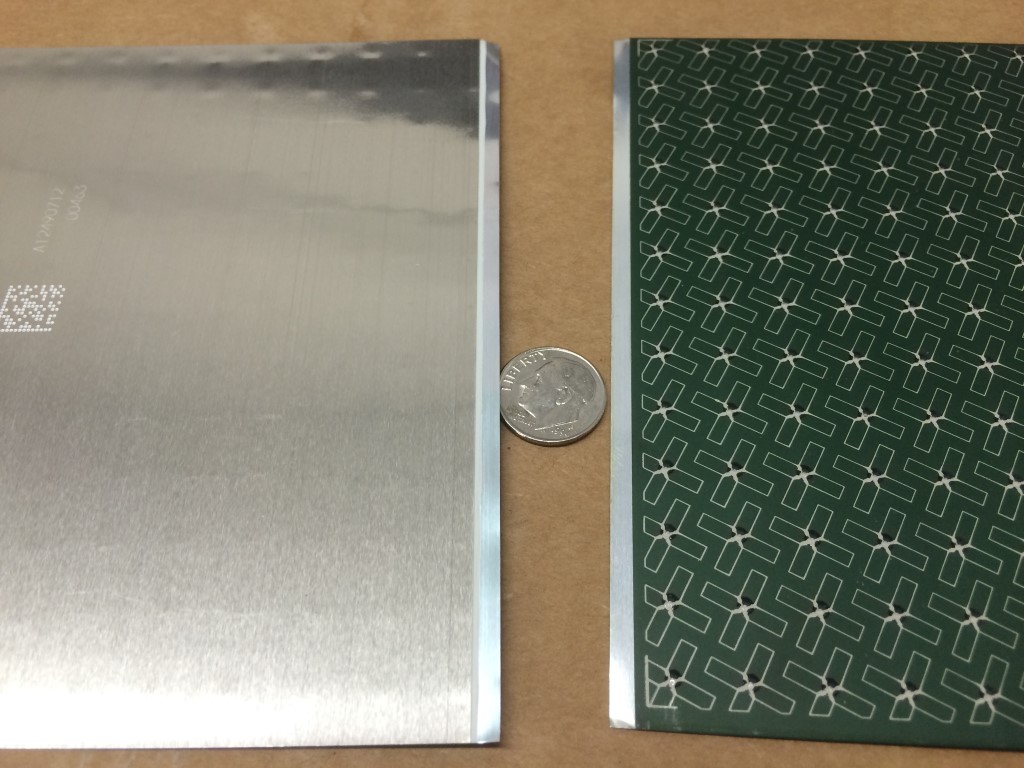

The metal (nickel coated aluminum) back is the positive output of the cell. The thin strip of un-coated aluminum on the down-facing side of the front is the negative output of the cell. To connect them we have used double-sided conductive acrylic adhesive tape made by 3M (1182 EMI Copper Foil Shielding Tape). In the factory, Nanosolar used ultrasonic metal spot welders to connect the cells. We have found that while a spot welder does connect them, if the settings are not just right you will blow a hole through them or make a weak connection. We believe a combination of the 3M 1182 tape and spot weld may be the best choice for DIY solar applications.

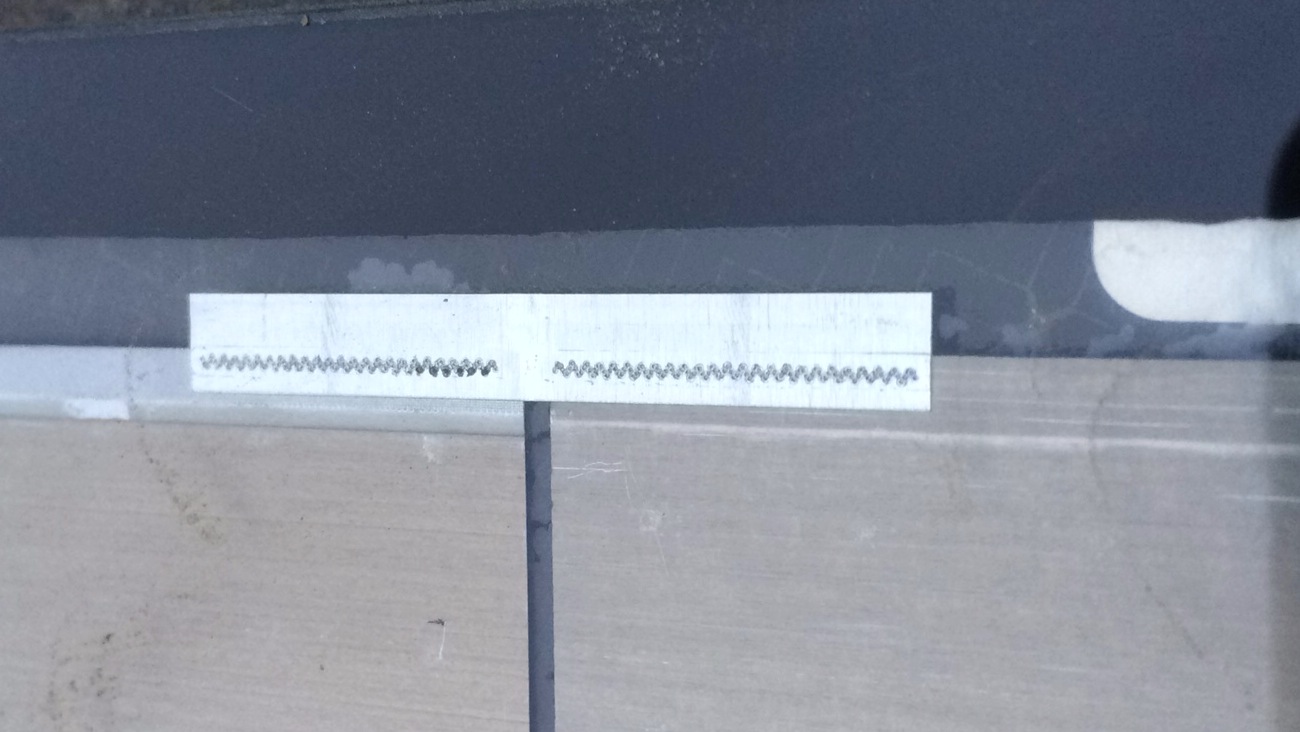

CONNECTING WITH CONDUCTIVE TAPE:

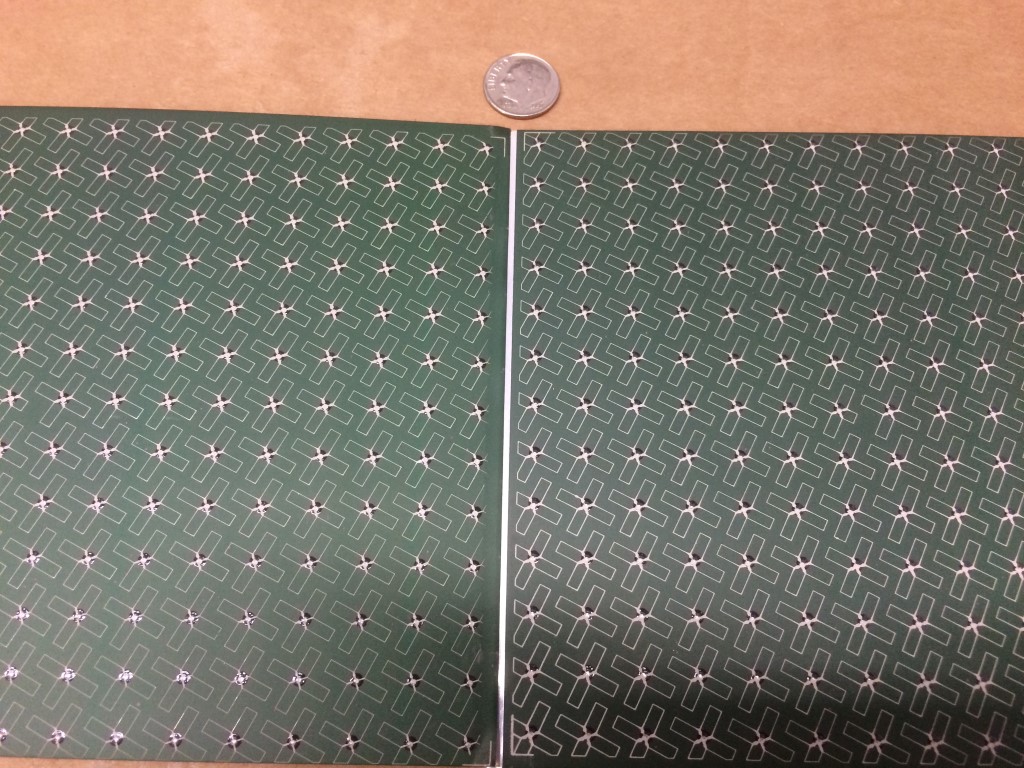

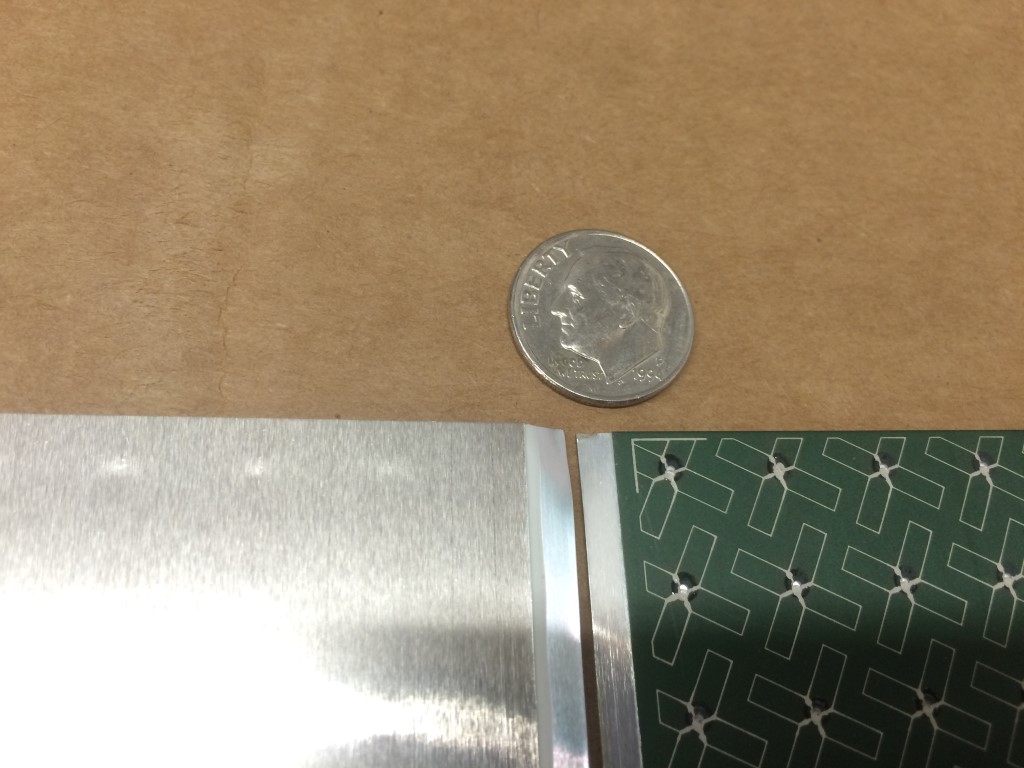

Again, the TOP side of cell is NEGATIVE and BOTTOM side is POSITIVE. Nansolar cells consist of two thin sheets of aluminum separated by a special energy producing layer that separates the two sheets. The bottom positive side of the cell has a thin layer of sputtered nickel coating it and will actually accept solder. The top layer is not coated and does not accept solder unless a special aluminum flux is applied first. Because the two sheets of the cell are different polarities negative (Top) and positive (Bottom) if those two sheets touch each other either by cutting or by overlapping the conductive tape, the cell will short. So, to connect the cells, apply double-sided conductive tape to the protruding top of the bottom aluminum sheet. Then take another cell and lay the protruding bottom of the top aluminum sheet so they connect. Be careful keep a small gap between cells because if they touch they will short. Here are some photos showing this:

-

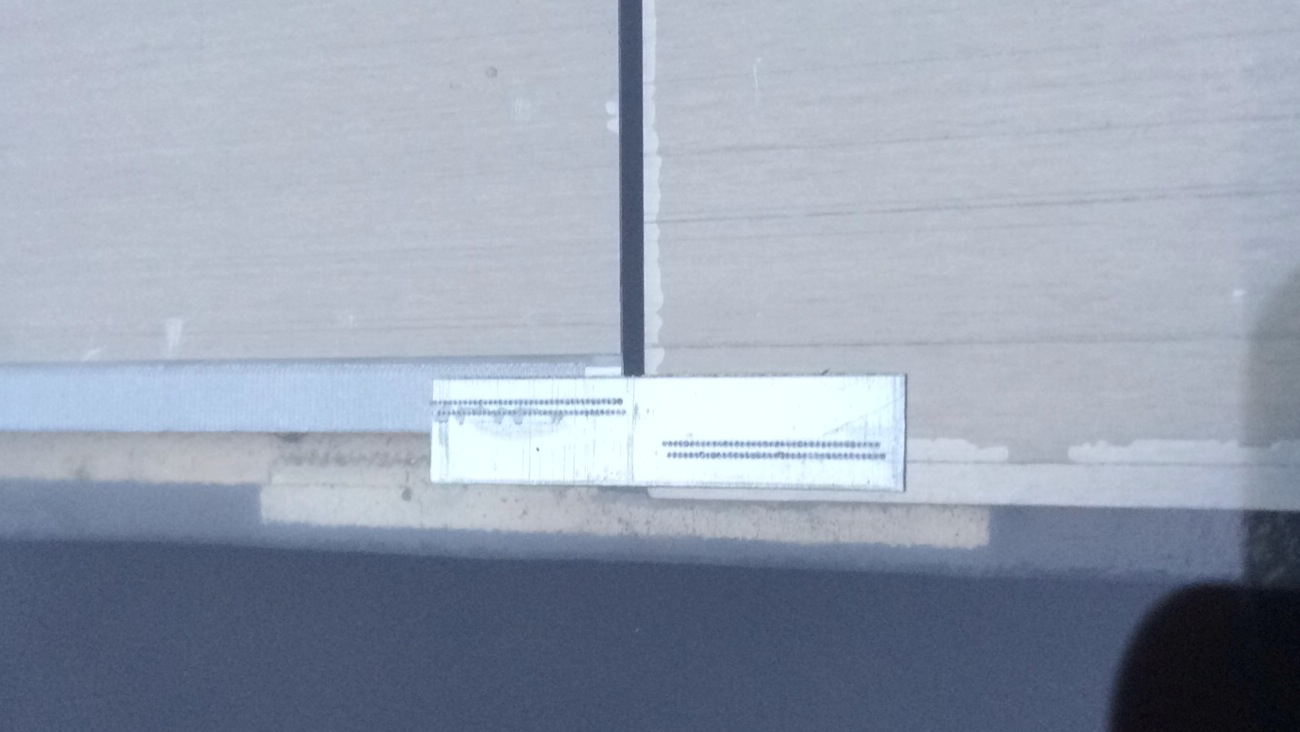

HOW NANOSOLAR CONNECTED THE CELLS:

Here are some photos that illustrate how Nanosolar connected the cells into complete panels.

Cutting solar cells

We have had many questions regarding cutting these cells. When these cells are cut they retain their .45 volts but the amps are reduced somewhat proportionally. You cannot use regular scissors or tin snips as the cells are made of 2 thin sheets of aluminum separated by energy producing compounds. If the top (negative) and bottom (positive) aluminum sheets touch it shorts the cell. We have successfully cut these cells with a water-jet cutter as well as a sharp bench shear set at 45 degree angle. It is possible to cut and then sand the cut edges back until the two sheets are separated but that is a tedious task and not recommended. Also we have noticed the cut cells are not as robust as the uncut cells even when accounting for the size differences of the cells.

Nanosolar Cells Specifications

Videos

Nanosolar Nanocell Flexible DIY Solar Cell Test for Power Output

We're happy to help

If you have questions or need assistance with your DIY solar project, please visit our contact page or give us a call at (805) 648-3300.