Description

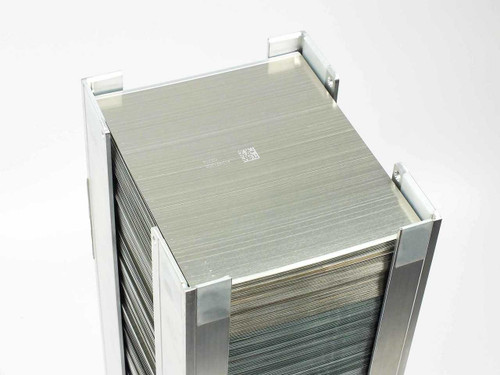

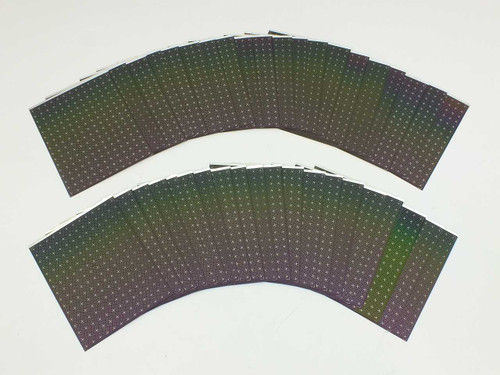

HISEC Yamashita Denso Solar Panel I-V Hi-Pot Solar Simulator Test Line (MX-III)

Manufactured by Hitachi Setsubi Engineering Co., LTD for Uni-Solar in 2010. The test line is used for final qualification of the condition of solar modules manufactured by a solar cell production line. Performance characterization by Solar Simulator and Hi-Pot test to inspect for electrical safety. The test line consists of the following major components.Load Conveyor (5,080mm x 2,420mm) for solar panels up to 18 feet in length with touch screen operator panel. Solar Simulator: Yamashita Denso (YDC) PXS-0855MP 6000mm x 900mm 10msec 40 KVA single flash pulse xenon lamp test system JISC8912 Class A and ASTM E927 Class A. I-V Curve Measuring System follows JIS C8913 and ASTEM. Measurement range 80V 15A. Measurement Points: 30 at 1000W/m2. Integrated Window XP based software testing analysis and touch screen operator panel. Hi Pot Tester designed to submerge and test voltage of 2 modules at a time with two Kikusui TOS9201 Voltage Testers with touch screen operator panel. Air Knife system blows off water on module surface after Hi-Pot test utilizing an 8.8kw blower. Overhead Pickup Transport Gantry: Pickup 1 conveys modules from load conveyor to solar simulator. Pickup 2 conveys modules from solar simulator to Hi-Pot testers. Pickup 3 conveys modules from Hi-Pot tester to unload conveyor. Gantry moves in vertical and horizontal direction to convey modules. Unload Conveyor (6,080mm x 3,420mm) picks up tested panels and conveys them to the take off position with touch screen operator panel. Power Distribution Panel: 208 Volts 3 Phase 300 Amp 60 Hz Required. Control Panel: 208 Volts 3 Phase 200 Amps Required. Software: Windows XP based software custom programmed for Uni-Solar panel specifications. System includes solar panel drill, cutter and pre and post load tables, spare parts, extra Xenon Lamps, complete manuals and schematics. Dimensions and Weight: 35 feet wide by 38 feet deep by 10 feet tall. Approximately 40,000 pounds. System will ship in approximately 4 40 foot containers.

View AllClose

Manufactured by Hitachi Setsubi Engineering Co., LTD for Uni-Solar in 2010. The test line is used for final qualification of the condition of solar modules manufactured by a solar cell production line. Performance characterization by Solar Simulator and Hi-Pot test to inspect for electrical safety. The test line consists of the following major components.